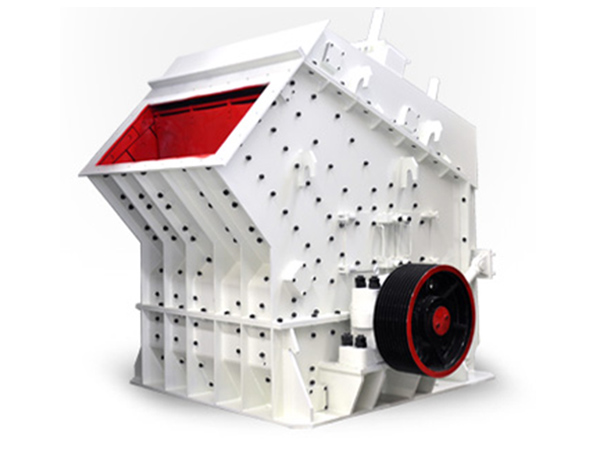

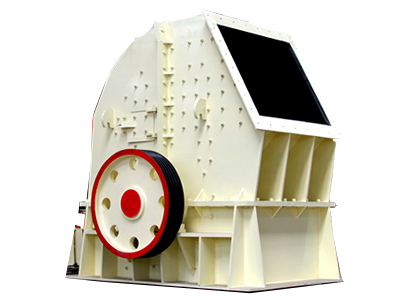

工作原理Operating principle

棒磨式制砂機由電機通過減速機及周邊大齒輪減速傳動或電低速同步電機直接通過周邊大齒輪臧速傳動,驅動筒體回轉,筒體內裝有

適當的磨礦介質一鋼棒。磨礦介質在離心力和摩擦力的作用下,被提升到一定高度,呈拋落或泄落狀態落下。被磨制的物料由給礦口連續

的進入筒體內部,被運動的磨礦介質所粉碎,并通過溢流和連續給礦的力量將產品排出機外,以進行下一段工序作業。棒膺產物的粒度特

性與棒磨碎礦石的情況有關。當棒打擊礦石時,首先是打著粗粒,而后才磨碎較小的礦粒,從而減少了過粉碎的危險。當棒沿襯板轉著上

升之時,其間夾著粗粒,好像棒條篩,讓細粒從棒的縫間通過,這也有利于夾碎粗粒,和使粗粒集中在磨礦介質打擊的地方。因此,棒磨

的產物較均勻,過粉碎較輕。

The rod mill type sand making machine is decelerated by motor through a reducer and surrounding large gears or is directly decelerated by a low—sped synchrongus motor through

the surrounding large gears, driving the simplified rotation, and the simplified is equipped with a suitable grinding medium—steel rod, The grinding medium i lifted to a certain

height under the action of centrifugal force and fictional force. and falls in a site of throwing or venting. The round material continuously enter th inaidenf th simnliieation

from the feeding port, is crushed by the moving grinding medium, and is discharged out of the machine through the force of overflow and continuoug feeding for the next process

operahon. The Article size characteristics ofrnd mil nnructs are related to there cnushed hy rod mils. When the rod hit the ore itirat hits the coarse nartiele,and then grinds

the smaller one articles, thereby reducing the risk of over-enushing. When the rod rotates and rises along the liner. the coarse articles are sandwiched in hetween. ike a rod sieve.

allowing the fine particles to pas through the gap between the rods, which is also conducive to crushing the coarse particles and concentrating the coarse particles in the grinding

medium. The place to hit. Therefore, the rod mil product is more uniform, and the over-crushing is lighter.